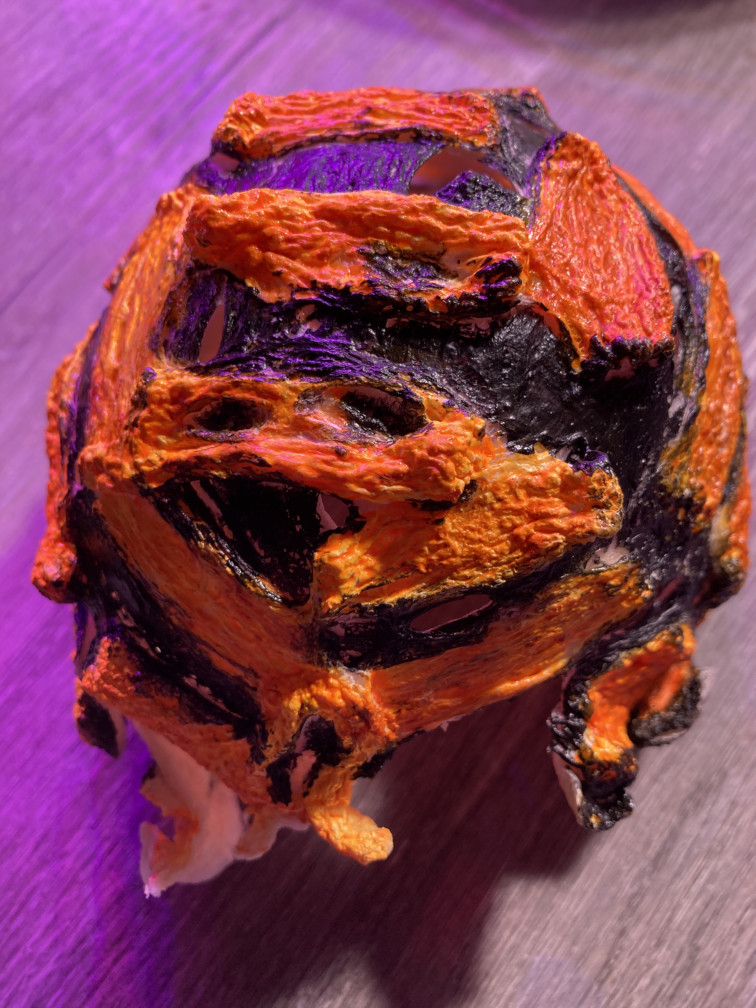

We recently did some PC necromancy and brought back a vintage computer system. This beast is a first generation Pentium 4, socket 423, TH7A-RAID, running @ 1.8Ghz, with 2GB RamBus memory, and a 230GB SSD. It takes forever to boot but when it does it is still pretty decent.

I am really surprised that this is a great system to capture DV video via firewire. I also found a surplus parallel port based DSO (Link Instruments 2102M) that runs perfectly in XP.

I really love keeping this system and the Link hardware alive.

Thanks for looking.

Please take care of each other.